Gate valve and globe valve are both multi turn valves, and is the most commonly used valve types in oil & gas, petrochemical, water treatment, mining, power plant, etc. Do you know what’s the difference between them?

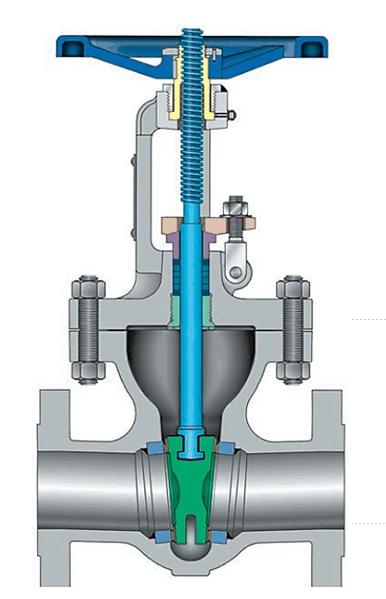

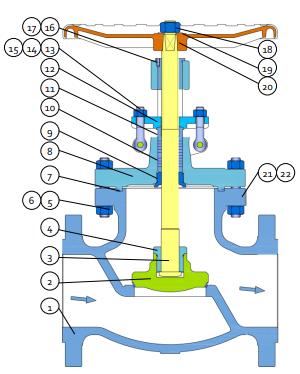

1.Appearance

Gate valve have different body appearance from the globe valve, and shorter face to face length, but of higher length than globe valve.

2.Disc

The globe valve disc is usually parallel to the fluid, while the gate valve disc is actually a gate and will be perpendicular to the direction of the fluid. Globe valves generally have no open rod and dark rod points, and gate valves generally have open rod and dark rod points. In addition, the height of the globe valve will be shorter than the gate valve, and the length will be longer than the gate valve.

3.Working Principle

The globe valve is a rising stem, and the handwheel rotates and rises with the stem. Gate valve is a hand wheel rotation, the stem to do rising motion.

4.Installation

When the globe valve is installed, the flow direction marked on the valve body needs to be installed, and the flow direction of the gate valve is the same from both sides.

5.Capacity & Function

Gate valve should be fully open, globe can be not fully open. Globe valves are generally used for pressure flow control and gate valves for isolation. The resistance of the globe valve to the flow of the fluid is generally large, and the resistance coefficient is generally between 3.5 and 4.5. Gate valves have less resistance to flow, with a coefficient of resistance ranging from 0.08 to 0.12, and the force applied to closing the valve is greater than that applied to opening it.

6.Shape

The disc of gate valve is a gate plate, the shape is relatively simple, and the casting technology is better; And the globe valve structure is more complex, with spherical, taper and plane spool, press down to the seat sealing, so globe valve is more difficult while casting.

7.Application Conditions

Gate valve open and close the required external force is small, fluid resistance is small, the flow of the medium is not restricted; Because of its structural characteristics, the globe valve flow resistance is large, in the opening and closing process there is always a very laborious. When the gate valve is fully opened, the erosion of the sealing surface by the working medium is smaller than that of the stop valve.

8.Sealing

Globe valve have better sealing performance than gate valve, but it’s a uni-directional valves, while gate valve is a bidirectional valve.

9.Size

Gate valve can be design to very big size even above 60”, but globe valve is not suitable to designed to very big size, normally applied as 28” and below.

10.Torque

Globe valve have higher torque value than the gate valve.

11.Repairing

Globe valve is easier to repair than the globe valve, because of it’s particular design.

Post time: Dec-01-2022

+86-577 6699 6229

+86-577 6699 6229